Al Sheet Metal Weldment

We don t recommend this as the best sheet metal welder.

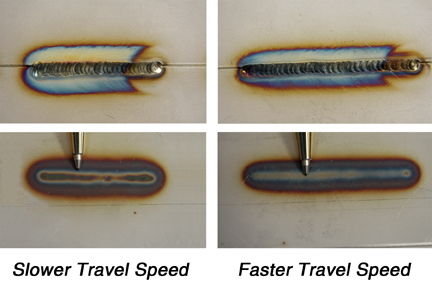

Al sheet metal weldment. For even thinner materials try a 035 inch filler metal. There are a few helpful settings for tig welding sheet metal like a downsloping adjustment but there are no upsloping or pulse arc functions. For sheet metal i use ine welding wire and it is just as good as their flux cored wire if you want you can grab one here. To prevent burn through and warping don t whip or weave the torch.

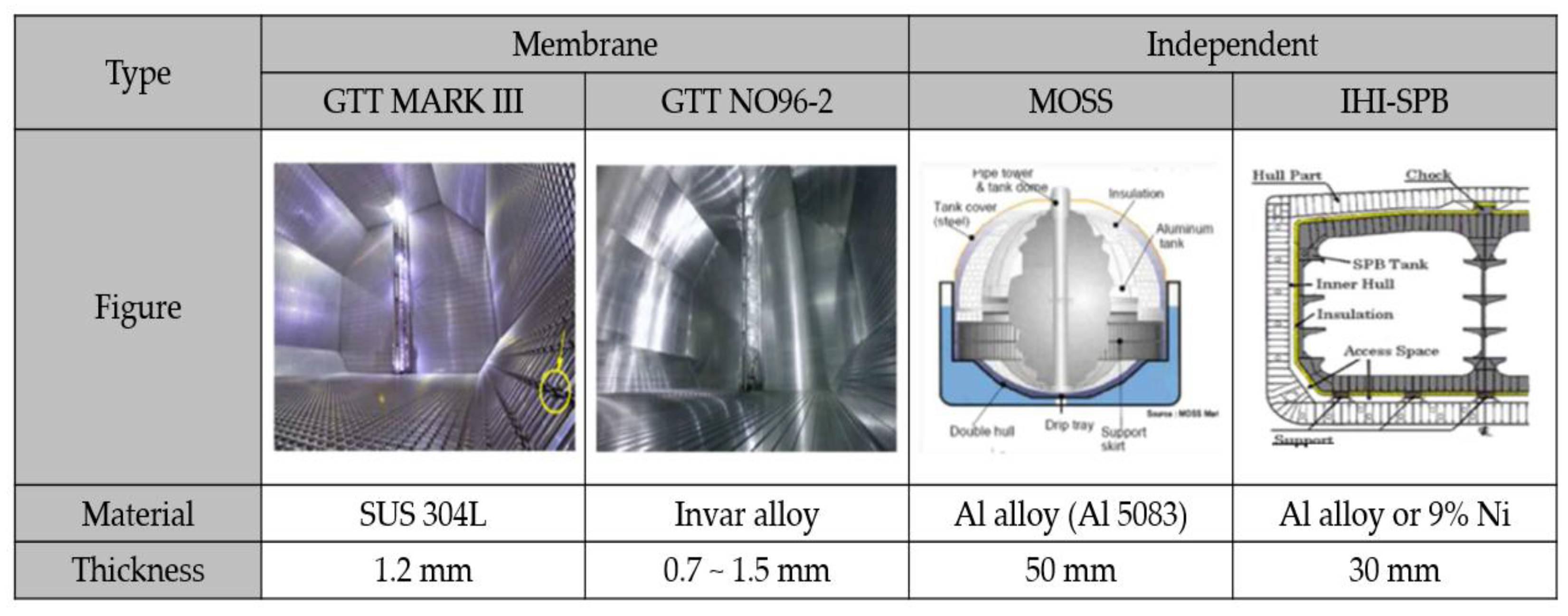

Short bursts or tacks will help. Filler metals for either of these would be 4043 or 4943. Learn the tricks to gas welding aluminum sheet metal with mike from cobra torches. A 5356 filler metal also works for 5052 materials specifically.

This is the final installment of a series which began in january and continued in may. The more time the arc is in an area the hotter it. Corrosion resistant 3003 aluminum texture selector packs. Steelworks 24 in x 48 in aluminum tread plate sheet metal.

Weld and cut in one kit with this torch from eastwood that s made in the u. These usually are used as welding or brazing filler alloys. However they are sometimes used as base materials. Item 241558 model 11256.

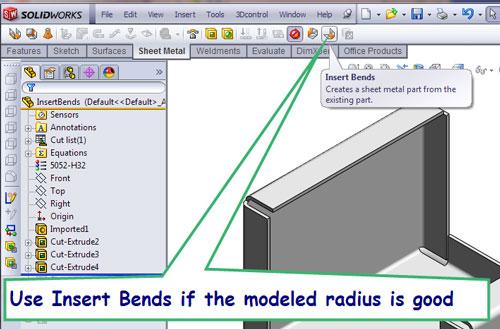

Try going for a wire of 023 inches when welding sheet metal. Weave diamond and tread. Take the time for proper fit up proper tight part fit up is especially important when welding thin materials. See tm technologies aluminum gas welding system.

For cv mig welding on sheet metal wire diameters of 035 inch are recommended. Welding aluminum body sheet from automotive body repair news december 1995. Easy to weld 5052 aluminum sheets and bars. Techniques for welding sheet metal.

The sheet features a union jack style perforated design. Includes one 1 1 2 3 0 032 thick piece of each texture. If that is the case they are readily welded with 4043 filler metal. The md building products 36 in.

All are readily weldable using either 4043 or 5356 filler metal. While wire feed welding sheet metal go for short bursts of welding instead of a going on a long bead. X 36 the md building products 36 in. A 100 argon shielding gas is the most common in mig welding aluminum sheet metal.

It is easy to work with and very attractive in the home. Mig gmaw skip welds tig gtaw tack welds ofw torch crater cracks alloys fillers. Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects. Typical aluminum alloys for sheet fabrication are 3003 and 5052.