Aircraft Cable Tensile Strength

Sku 45503 unspsc 31151703 manufacturer equiprite this is a catalog item.

Aircraft cable tensile strength. This has forced engineers to develop numerous sizes and styles which in turn has helped to. Most wire ropes feature six strands each of which has 15 66 wires. Diameter ininches coated to construction minimum break strength lbs. 1 8 7x19 minimum break strength 2000lb galvanized cable.

Galvanized aircraft cable provides high tensile strength and adequate corrosion resistance for most commercial applications. Wire rope uses include its original applications in the aerospace industry to hoisting cranes. A number of different types of wire rope also known as aircraft cables are currently on the market which might make it difficult for you to decide on the option that s best for your construction project. Available in diameters from 1 8 inch with a tensile strength of 1 760 pounds to 3 8 inch with a tensile strength of 12 000 pounds.

The higher the wire count the stronger the strand. The wire rope can be cut to order by foot to meet the requirements of any applicable system. Rope diameter minimum breaking strength safe load weight in mm lb f kn lb f kn lb m ft kg m 1 4. Aircraft cable sizes range from 1 32in to 3 8in with breaking strengths tensile strengths ranging from 120 pounds to 14 400 pounds.

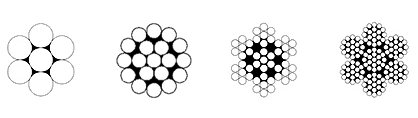

The guardian fall protection wire rope is 3 8 inch thick aircraft cable that possesses a 14 400 pound tensile strength. Our aircraft cable comes in 1x7 strand 1 x19 strand 7x7 strand and 7x19 strand all in galvanized steel or stainless steel. Stainless steel 7 x 19 aircraft cable. Out of stock online.

Stainless steel cable provides slightly lower tensile strength but greater resistance to corrosion. Must be used with drop forged clamps in horizontal lifeline applications in accordance with system instructions and the judgment of. Purchase in lengths from 100 feet to 5 000 feet. Commercial quality aircraft grade cable is made from galvanized steel wire or stainless steel wire.