Air Receiver Tank Function

The compressed air leaving a vertical receiver tank should always be at a higher level than the inlet port.

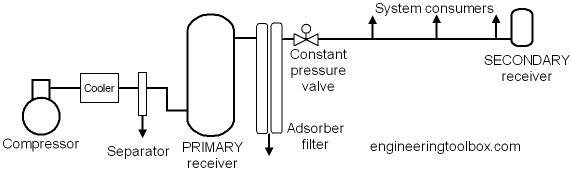

Air receiver tank function. The tank is sized 6 10 times the flow rate of the compressor system. The receiver tank is usually 150 cubic feet minimum for compressors with a rating of 25 scfm at 100 psi. Dampens pulsations from the discharge line of a reciprocating compressor resulting in an essentially steady flow of air in the system. Types of air receiver tanks.

So if a compressor has a rating of 25 scfm at 100 psig the receiver tank should be 50 gals minimum up to 250 gals if there are. Will walks you through the what it does and why it is important. Call us at 8. An air receiver tank is an important component of a compressed air system.

For other cases a separate. Continue reading for more background on air receiver tanks and their effects on air systems. Air receiver tanks actually play an incredibly important role in the overall compressed air system. V t c p a.

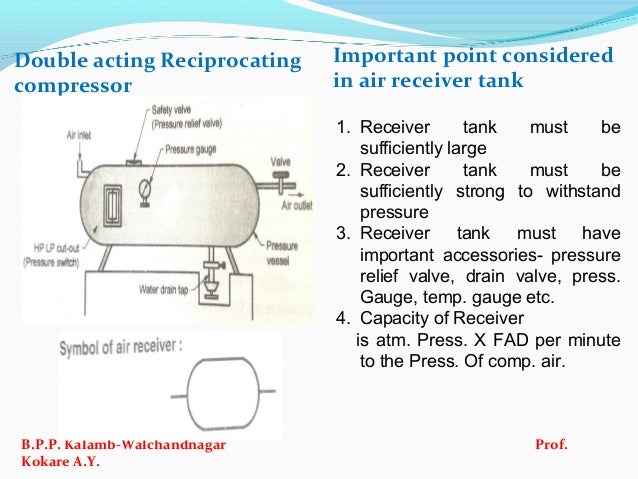

An air receiver tank is an integral and important part of any compressed air system. An air receiver sometimes referred to as a compressed air tank is an integral part of any compressed air system. Typically a receiver tank is sized at 2 gal scfm and increased to 4 10 gal scfm of flow if there are big demand swings or surges. The reason for this is that the moisture and other contaminants which condense out of the incoming compressed air collect in the bottom of the receiver tank.

Wet tanks and dry tanks the major difference between them is their. The main purpose of this is to act as temporary storage to accommodate the peaks of demand from your system and to optimize the running efficiency of your plant. It stores compressed air that can be used for short high demand events. An air receiver tank provides temporary storage for compressed air.

It also helps your air compression system run more efficiently. Air receiver tanks serve many important functions and roles within an air compressor system. With very small air compressors the function of the aftercooler ie the lowering of the dewpoint of the compressed air is performed by the air receiver. The tank is a reservoir of compressed air that can be used during peak demand.

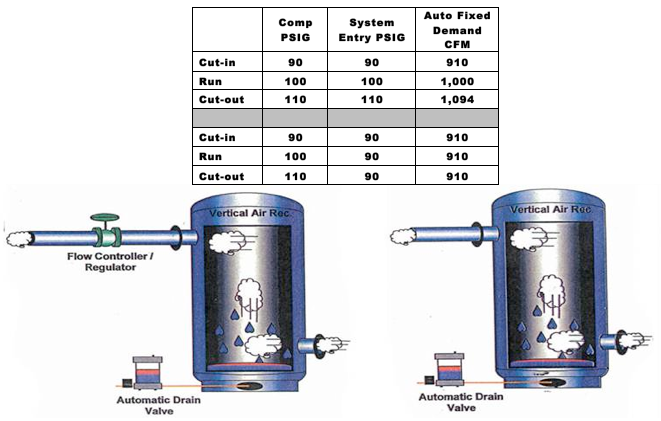

For an air compressor system with mean air consumption 1000 cfm maximum tank pressure 110 psi minimum tank pressure 100 psi and 5 sec time for the receiver to go from upper to lower pressure the volume of the receiver tank can be calculated by modifying 1 to. Looking for more information on compressed air receiver tanks. These liquid contaminants are normally drained away however should the drain. It provides a steady air signal to compressor controls.

Two main types of air receivers exist. An air receiver tank.