Air Flow Switch Operation

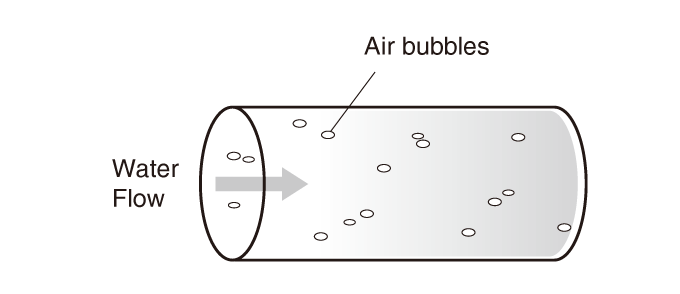

Flow switches are mechanical devices used in controlling the flow of air steam or liquid.

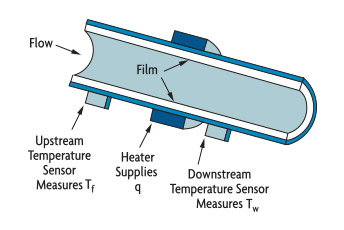

Air flow switch operation. Learn more about the technology and operating principles behind gems sensors and controls broad portfolio of sensing products by accessing our operating principles for level pressure flow conductivity relays and barriers and ultrasonic products. When the pressures from two different sources in a process are connected across the sensing diaphragm metallic or elastomeric as the case may be the pressure difference creates a force which then overcomes that of a pre tensioned spring and in the process moves a balancing arm or mechanism to effect the minimal movement required to actuate the micro switch es of the switch. Sometimes pressure switches are employed to designate deficient pressure to ensure that the required flow is maintained. Flow switch operating principle is based on a free floating magnetic piston which responds only to the motion of fluids within the line not to static or system pressures.

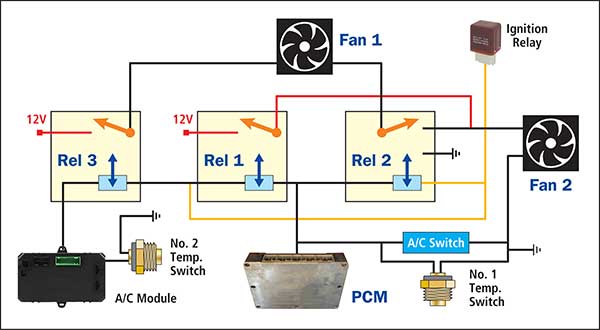

This switch can be used to actuate audible or visual alarms as well as relays or other controls. If you receive an error code when you try to turn the hot tub or spa on troubleshooting the flow switch can help indicate where a problem exists. Airflow actuated hvac switches use this switch to sense changes in airflow velocity. It is necessary to provide damage protection and circuit cooling or adjust flow rates that are too high or too low.

In the presence of fluid flow controlled movement of the piston actuates an external hermetically sealed reed switch. Aflow switchoperates by conveying a trip motion relay reed switch paddle to another machine within the system usually a pump. Often used to detect clogged air filters and iced air conditioner coils these switches sense small changes in pressure between two points in your duct. Rely on grainger for a wide range of duct pressure switch options.

An air switch senses positive negative or differential air pressure and actuates an internal switch. The flow switch is factory set to switch at 195 fpm. To handle air velocities greater than 920 fpm the paddle may be cut at a precalibrated mark. Draft inducer and pressure switch operation the draft inducer motor is a blower that creates a flow of combustion air through the furnace s heat exchanger s to make sure all combustion exhaust byproducts are vented outside the home via the flue vent.

Air flow exerts a force on a paddle actuating a dust tight spdt micro switch. The switching point may be adjusted continuously within a wide range making the lps useful in a wide variety of applications. Flow switches are used in spas and hot tubs to tell the system to turn on and off. The principle of operation is quite simple.

The trip signal will indicate to the pump to turn on or turn off.