Air Dryer Purge Tank

Reservoir ad is air dryer brand.

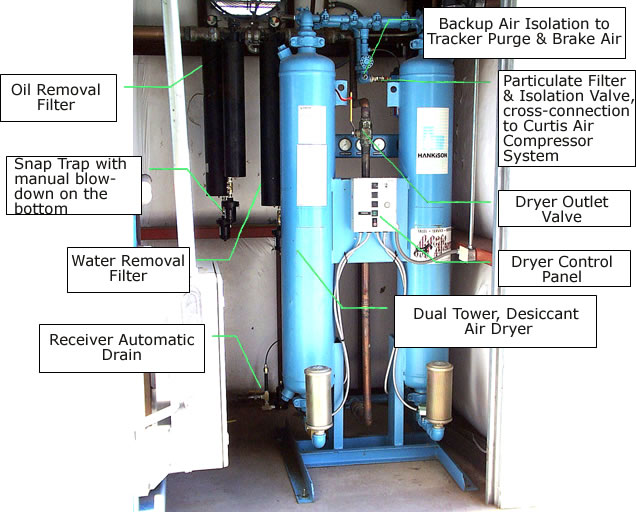

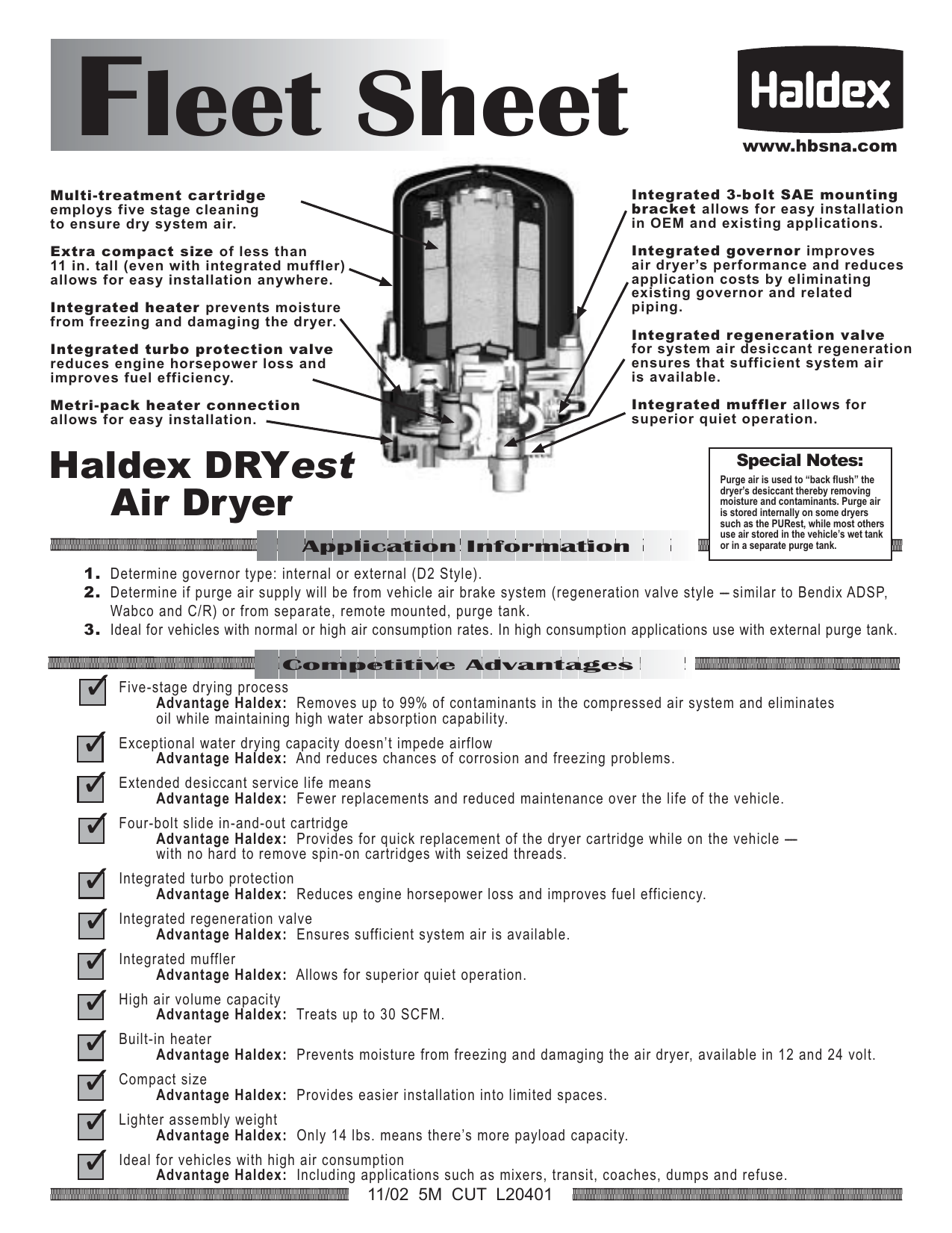

Air dryer purge tank. Dryer leaks from purge valve during compressor loaded cycle. Purge valve frozen open cold weather operation. Bendix bendx unit of measure. Add to this the cost for the pressure differential of the dryer and associated filters and the cost becomes 3 5 to 4 5 kw per 100 cfm at full load.

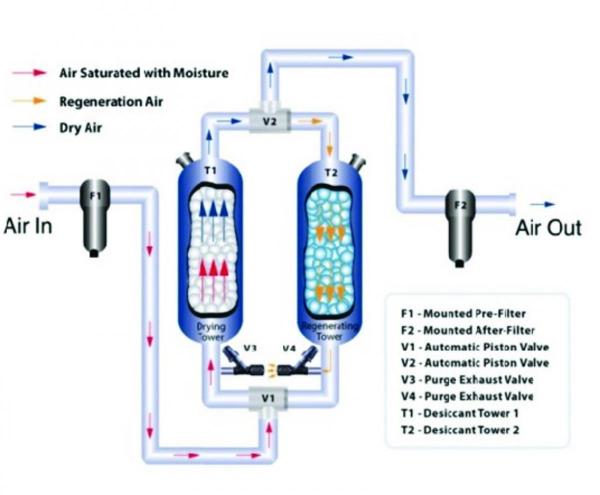

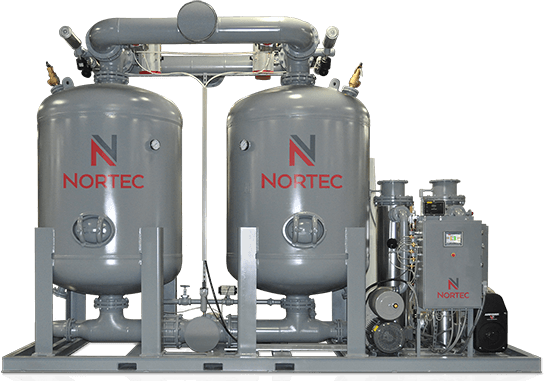

Regeneration style air dryers dedicated purge tank air dryers solution. The bendix ad 9 air dryer alternates between two modes or cycles during use the charge cycle and the purge cycle. Both cycles play an important part in keeping your air tanks as clean as possible. Air dryers are constructed of a lightweight aluminum and steel housing with a unique spin off cartridge.

As the atmospheric air is compressed all the water. If so think of the tank drains as the report card for the health condition of the air dryer. The design of these air dryers serve vehicle vocations with compressor duty cycles of up to 40. The purge tank stores clean dry air for regeneration of the desiccant bed.

With an ad 9 air dryer installed contaminants enter the supply port of the air dryer end cover. As the service reservoir air pressure drops to the cut in setting of the governor the governor returns the compressor back to building air and the air dryer to air drying mode. To stop the compressor from building air and also causes the air dryer to purge. If the compressed air is generated at an average specific power of 20 kw per 100 cfm at the compressor the cost of the purge air is about 3 to 4 kw per 100 cfm of dryer nameplate rating.

Compressed air dryers are special types of filter systems that are specifically designed to remove the water that is inherent in compressed air. 013 010 495 tank purge air drier. The air dryer s job is remove both water and oil the oil lubes the compressor so a minute amount gets into the air system. Yes the big if is whether you have an air drier.

The process of compressing air raises its temperature and concentrates atmospheric contaminants primarily water vapor. The leak may cause excessive compressor cycling or prevent the system from building air pressure.